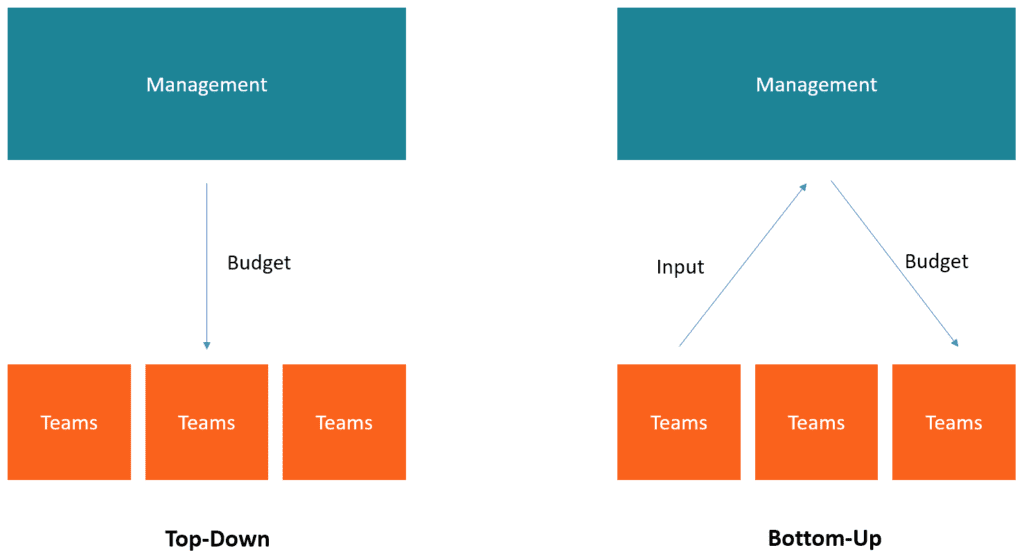

Bottom–up thinking is said to take place through taking in details and building up from there. The fragmented bits and pieces are structured and categorized, and then induction is made—a process that brings rise to something.

Top–down processing, on the other hand, refers to the perception driven by cognition.

In the best of situations, those asking for estimates are often in management, and the key to the project’s success is when they realize calculations require conversation.

This past week I have worked on four very intense and convoluted projects. The client is coming to me with a project they often try to complete. Most of the time, the management has already set a budget. When this is the case, we spend time going back and forth to see what we can do within their budget.

I have one client that came to me looking for the Bottom-Up approach. They are in the budgeting phase for a significant project. I helped them with a similar project in another part of the country. They are asking me to duplicate that in a new location.

The problem is that the person asking for the Estimate was not involved in all the parts of the last project. I have to educate them on the details of the estimate that are much more involved than what they think was involved.

When most people see a video of an interview that is under a minute, they think that is all it took to get that interview. This is one of the parts of the estimate I had to explain to the client.

Here is the gist of my education on the topic of a video interview.

While you may see a 30 to 90-second interview, almost all the ones you noticed that we produced took about 3 to 4 hours to shoot. That includes the time to set up the cameras, lights, and microphone and take it down. The actual time we interviewed was about 30 minutes.

I then take those interviews for a first rough cut. I take out all the questions and significant pauses and create a video that is often first reviewed by another team member. That person is often the writer/editor. Then they send back time codes, and we put together the first actual edit. This includes the lower third graphics. Then this is shown to another person up the chain before we offer it to the main client.

The video has usually gone through about 4 to 5 revisions when the client sees it and makes their changes. This is usually about 8 to 10 hours of editing and reposting this online for the team to review.

The purpose of all this is to help explain why what they think is just a few minutes will be a couple of days of work, and that is why the estimate must reflect the behind the scene position they often do not see.

This is Bottom-Up thinking.

The problem with those who do not understand the importance of the Bottom-Up thinkers working with Top-Down thinkers is that the American Automobile declined from the 1960s till almost the 1980s. Meanwhile, Japan overtook the market around 1970 with the help of Dr. William Edward Deming.

William Edwards Deming (1900-1993) is widely acknowledged as the leading management thinker in the quality field. He was a statistician and business consultant whose methods helped hasten Japan’s recovery after the Second World War and beyond. He taught that by adopting appropriate management principles, organizations could simultaneously increase quality and costs (by reducing waste, rework, staff attrition, and litigation while increasing customer loyalty).

Today most people know his work at Total Quality Management and link this to Toyota rather than Deming, who created it. He broke it down into a cycle.

The Deming Cycle, or PDCA Cycle (also known as PDSA Cycle), is a continuous quality improvement model consisting of a logical sequence of four repetitive steps for continuous improvement and learning: Plan, Do Check (Study), and Act.

Estimates are only as good as the information given to the person creating the forecast. Deming understood that as you work on something like a car, it is often the front-line worker who will first see a problem. They need the power to stop the assembly line to be sure the customer gets the best product.

Estimates are needed for Ex Nihilo [out of nothing] work. This is where something is required to be created versus buying something already in existence.

Bottom Line Take Away

Working on estimates can be pretty frustrating to everyone. They are so disappointing because the customer is asking for the estimate. They cannot go forward with the project if they don’t know what they are getting and the cost of it. For the one writing the estimate, they need all the information to create it, but most of the time, the customer doesn’t know all they need to know–this, they are asking for an estimate.

Customers need to be realistic about the process of creating an estimate. They should never think they can continue asking for revisions without compensating for this work.

The one doing the estimating is doing some of the work you need to be done to go to your bosses to give them the feedback they need for budgeting and making decisions.

If you are the one creating estimates, I believe there comes the point in the process of revisions that you are perfectly entitled to compensation. You are doing all the heavy lifting, and the client can take all your work and shop for someone to implement your estimate for a lower rate.

Most of the time, the one doing the estimating is doing the most creative work for a project. They need to be compensated. Also, don’t forget that people will not pay for your first estimate. There will be some give and take, but at some point, the client needs to compensate for all those revisions if they want more clarity in the estimate.